This manual provides a comprehensive guide for installing, operating, and maintaining the XNX Universal Transmitter, ensuring optimal performance and compliance with international safety standards.

Overview of the XNX Universal Transmitter

The XNX Universal Transmitter is a versatile gas detection solution supporting electrochemical, infrared, and catalytic bead sensor technologies. Designed for flexibility, it offers multiple mounting options and communication protocols like HART, Modbus, and Fieldbus. Its rugged design ensures reliability in hazardous areas, with Class 1/Class 2 intrinsic safety certification. The transmitter simplifies installation and reduces costs by accommodating various sensor types and configurations, making it suitable for diverse industrial applications. Its advanced features and compatibility with global standards ensure seamless integration and operation.

Importance of Proper Installation and Safety Precautions

Proper installation of the XNX Universal Transmitter is critical for ensuring optimal performance, reliability, and safety. Adhering to safety guidelines prevents potential hazards, such as electrical shocks or gas detection failures. Always follow international standards and manufacturer recommendations to avoid risks. Grounding the sensor correctly is essential for intrinsic safety, while avoiding enclosure opening under power prevents dangerous situations. Compliance with these precautions ensures reliable operation and protects personnel from potential hazards, making safety a top priority throughout the installation process.

Safety Considerations and Precautions

Ensure proper grounding, avoid opening enclosures under power, and follow intrinsic safety guidelines to prevent hazards and maintain compliance with international standards during installation.

General Safety Guidelines for Transmitter Installation

Adhere to all safety guidelines to ensure safe and reliable XNX transmitter installation. Proper grounding is essential to prevent electrical hazards. Avoid opening the transmitter enclosure under power unless the area is confirmed non-hazardous. Use only certified M25 cable glands for installation. Follow recognized international standards for hazardous area compliance. Ensure the sensor is earthed/grounded for intrinsic safety. Consult the manual for specific warnings and cautions before proceeding with any installation tasks. Always prioritize electrical safety to avoid potential risks and ensure compliance with global regulations.

Intrinsic Safety and Hazardous Area Compliance

The XNX transmitter is designed for safe operation in hazardous areas, meeting global intrinsic safety standards. Ensure proper grounding and use certified M25 cable glands to maintain intrinsic safety. The transmitter is certified for installation in Class 1/Class 2 areas worldwide. Always follow regional safety regulations and guidelines for hazardous environments. Proper grounding prevents electrical hazards and ensures compliance with international standards. The XNX Universal Transmitter is built to operate safely in diverse industrial settings, adhering to strict safety protocols for reliable performance.

Technical Specifications of the XNX Transmitter

The XNX Universal Transmitter supports electrochemical, infrared, and catalytic bead sensors, with communication options including HART, Modbus, and Fieldbus, and operates on Class 2 power supply.

Supported Sensor Technologies (Electrochemical, Infrared, Catalytic Bead)

The XNX Universal Transmitter is compatible with multiple sensor technologies, including electrochemical, infrared, and catalytic bead sensors. These technologies provide accurate detection of toxic and flammable gases. The electrochemical sensors offer high sensitivity for toxic gases, while infrared sensors ensure reliable detection in harsh environments. Catalytic bead sensors are ideal for flammable gas monitoring. The transmitter’s flexibility allows it to support various Honeywell Analytics gas sensors, ensuring tailored solutions for diverse industrial applications. This versatility simplifies installation and reduces costs.

Communication Protocols (HART, Modbus, Fieldbus)

The XNX Transmitter supports industry-standard communication protocols, including HART, Modbus, and Fieldbus, enabling seamless integration into various control systems. HART provides advanced diagnostics and configuration, while Modbus ensures compatibility with legacy systems. Fieldbus supports high-speed data transfer for large-scale industrial applications. These protocols enhance connectivity, allowing for efficient data exchange and device management. This flexibility ensures the transmitter can meet the communication requirements of modern industrial environments, facilitating real-time monitoring and control.

Power Supply Requirements and Class 2 Power Options

The XNX Transmitter requires a Class 2 power supply, operating within a 15-30 VDC range, ensuring safe and efficient operation in hazardous areas. Class 2 power options are designed to limit energy levels, reducing the risk of ignition in explosive environments. Proper wiring and voltage drop calculations are essential to maintain system reliability. The transmitter is certified to meet international safety standards, including IEC and NEC requirements, ensuring compliance and robust performance in industrial settings. This configuration supports intrinsic safety and seamless integration into hazardous area applications.

Installation Steps and Best Practices

Proper installation ensures optimal performance and safety. Begin with site preparation, secure mounting, and correct wiring. Follow guidelines for sensor alignment and connections to avoid errors.

Site Preparation and Mounting Options

Ensure the installation site is safe, non-hazardous, and suitable for the transmitter. Choose a location with optimal sensor exposure and minimal interference. Use metric or NPT threaded ports for secure mounting, and consider ruggedized options for harsh environments. Proper grounding is essential for intrinsic safety. Follow Honeywell’s guidelines for alignment and spacing to ensure accurate readings. Verify all connections and wiring before powering up to avoid errors or damage.

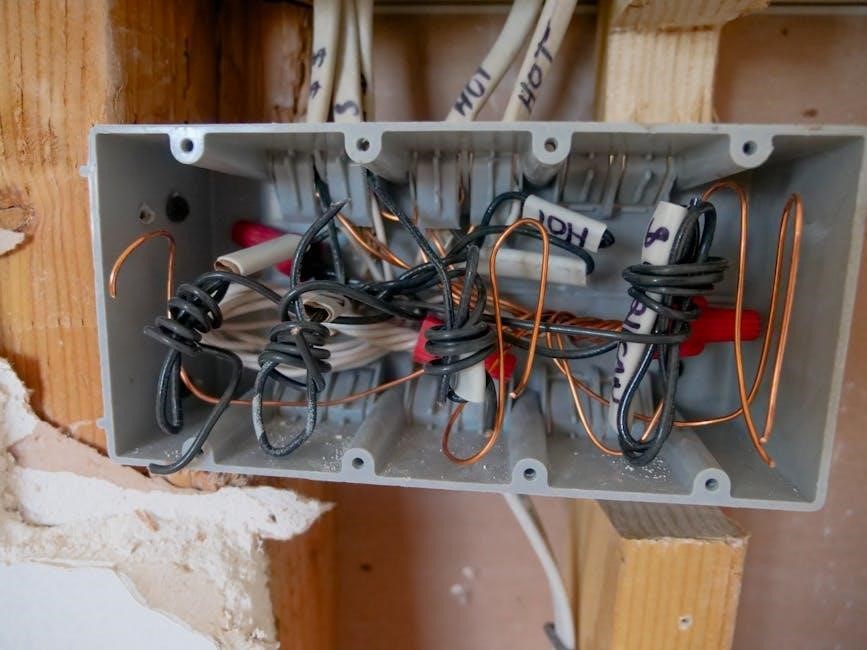

Wiring Considerations and Voltage Drop Calculations

Proper wiring is critical to ensure reliable operation of the XNX Transmitter. Use shielded, armored cables to minimize electrical noise and voltage drops. Calculate voltage drops to confirm the power supply meets requirements, especially for long cable runs. Ensure all connections are secure and grounded to prevent interference. Follow Honeywell’s guidelines for wiring to avoid damage or malfunctions. Correct wiring ensures accurate communication setups, including HART and other protocols, and maintains intrinsic safety standards for hazardous environments.

Connecting Sensors and Remote Installations

The XNX Transmitter supports various sensor technologies, including electrochemical, infrared, and catalytic bead, ensuring compatibility with Honeywell’s range of gas detection solutions. Remote installations are simplified with appropriate accessories, allowing sensors to be connected locally or remotely. Proper grounding and shielding are essential to maintain signal integrity and prevent interference. Follow the manufacturer’s guidelines for sensor mounting and wiring to ensure optimal performance and compliance with safety standards. This flexibility enables seamless integration into diverse industrial environments while minimizing installation challenges.

Sensor Mounting and Configuration

The XNX Universal Transmitter supports various sensor types, offering flexible mounting options and ensuring compliance with intrinsic safety standards for reliable gas detection.

Choosing the Right Sensor for Your Application

Selecting the appropriate sensor for your XNX Transmitter ensures accurate gas detection and reliable performance. Consider factors like gas type, concentration, environmental conditions, and intrinsic safety requirements. The XNX supports electrochemical, infrared, and catalytic bead sensors, each suited for specific applications. Electrochemical sensors are ideal for toxic gases, while infrared sensors excel in hydrocarbon detection. Catalytic bead sensors are best for flammable gases. Always consult the technical manual for compatibility and configuration guidelines to optimize system performance and safety.

Configuring the Sensor with the XNX Transmitter

Proper sensor configuration is critical for accurate gas detection. Connect the sensor to the XNX Transmitter, ensuring electrical connections are secure and compatible. Configure sensor-specific parameters, such as gas type and range, using the transmitter’s interface or HART software. Refer to the technical manual for detailed setup instructions. Verify intrinsic safety requirements and ensure the system is grounded. Always follow safety guidelines and test the configuration to confirm proper operation before deploying in hazardous areas.

Wiring and Connections

Proper wiring ensures safe and efficient transmitter operation. Use Class 2 power supply options and follow HART protocol guidelines for communication. Ensure all connections are secure and meet intrinsic safety standards.

Power Supply Wiring and Class 2 Requirements

The XNX Transmitter requires a Class 2 power supply to ensure safe operation in hazardous areas. Use certified cables and follow wiring guidelines to prevent voltage drops. Proper grounding is essential for intrinsic safety. Refer to the technical manual for specific power supply configurations and compliance with international standards. Always verify that the power source matches the transmitter’s requirements before installation to avoid electrical hazards and ensure reliable performance.

Communication Wiring and HART Protocol Setup

Connect the XNX Transmitter using standard 4-20mA wiring and HART protocol for advanced communication. Ensure proper shielding to minimize electrical noise. Use compatible cables and follow the technical manual for wiring diagrams. Configure HART settings to enable seamless communication with connected devices. Verify device compatibility and settings before startup. Proper communication wiring ensures accurate data transmission and optimal system performance, adhering to industry standards for safe and reliable operation.

Calibration and Testing

Calibrate the XNX Transmitter for accurate gas detection, following procedures for electrochemical, infrared, and catalytic bead sensors. Perform thorough system testing post-installation to ensure reliable operation and safety.

Calibrating the Transmitter for Accurate Measurements

Calibrating the XNX Transmitter ensures precise gas detection. Refer to the technical manual for specific calibration procedures tailored to sensor types: electrochemical, infrared, or catalytic bead. Use certified calibration gases and follow sequences meticulously. Post-calibration, verify sensor response and adjust settings as needed. Regular recalibration is essential for maintaining accuracy, especially in hazardous environments. Always adhere to safety protocols during calibration to prevent errors and ensure reliable performance. This step is critical for optimal system functionality and compliance with safety standards.

Testing the System After Installation

After installation, perform a thorough system test to ensure all components function correctly. Verify power supply stability and check for proper communication protocol operation, such as HART or Modbus. Test sensor response to target gases and ensure accurate readings. Validate remote installations and wiring integrity. Conduct environmental tests to confirm system robustness under varying conditions. Document all test results for future reference and compliance checks. Ensure grounding and intrinsic safety measures are intact to prevent electrical hazards. This step ensures reliable performance and adherence to safety standards.

Maintenance and Troubleshooting

Regular maintenance ensures optimal performance and safety. Check sensors, wiring, and power supply integrity. Troubleshoot common issues like sensor drift or communication errors promptly for reliable operation.

Regular Maintenance Tasks for Optimal Performance

Perform routine checks on sensors, wiring, and power supply to ensure reliable operation. Clean sensors to prevent contamination and verify intrinsic safety grounding. Inspect wiring for damage or wear, especially in hazardous areas. Check power supply voltage and ensure Class 2 compliance. Regularly review error codes and system logs to identify potential issues early; Calibrate sensors as recommended to maintain measurement accuracy. Schedule periodic transmitter software updates to incorporate performance enhancements and security patches. Ensure all components are properly grounded and sealed to prevent environmental interference. Always refer to the technical manual for specific maintenance intervals and procedures tailored to your installation environment. Regular maintenance not only extends equipment lifespan but also ensures compliance with safety standards and uninterrupted system operation. By adhering to these tasks, you can prevent unexpected downtime and ensure the XNX transmitter operates at peak performance.

Troubleshooting Common Issues and Error Codes

Identify and resolve common issues by checking error codes in the system logs. Verify sensor connectivity and ensure proper grounding to prevent noise interference. Inspect wiring for damage or loose connections, which can cause voltage drops or communication failures. Check power supply voltage to confirm it meets Class 2 requirements. Review calibration settings to ensure accuracy and perform recalibration if necessary. Consult the technical manual for specific error code explanations and corrective actions. Addressing issues promptly prevents downtime and ensures reliable operation. Always refer to the manual for detailed troubleshooting procedures.

Ensure all installation steps are completed and verified for compliance with international standards. Conduct a final inspection of wiring, sensors, and system configuration to confirm proper operation and safety.

Ensuring Compliance with International Standards

Ensure the XNX Universal Transmitter is installed in accordance with recognized international standards and certifications, such as ATEX and IECEx. Verify that all components, including sensors and wiring, meet local regulatory requirements. Proper installation, as outlined in this manual, guarantees compliance with intrinsic safety standards and hazardous area classifications. Always use certified accessories, such as M25 cable glands, to maintain compliance. Adherence to these standards ensures safe and reliable operation in global hazardous environments.

Final Inspection and System Verification

Conduct a thorough final inspection to verify all components are correctly installed and configured. Check wiring connections, sensor mounting, and transmitter settings. Ensure the system operates within specified parameters and that all safety features are functional. Perform a full system test, including communication protocols and alarm responses. Verify compliance with installation standards and document the results. This step ensures the XNX Universal Transmitter is ready for safe and reliable operation in hazardous environments.