The installation of PVC electrical conduit requires precision and adherence to guidelines to ensure safety and durability. This process involves cutting, bending, and securing conduits properly. A comprehensive guide, often available as a PVC Electrical Conduit Installation Guide PDF, provides detailed instructions and best practices for professionals. It covers essential steps, from site preparation to solvent welding, ensuring compliance with electrical standards and regulations. This resource is invaluable for contractors, electricians, and engineers aiming to achieve reliable and long-lasting electrical systems.

Overview of PVC Conduit

PVC conduit is a durable, corrosion-resistant material widely used for protecting electrical wires in various installations. It offers excellent resistance to chemicals and environmental factors, making it ideal for both indoor and outdoor applications. PVC conduit is lightweight, easy to cut, and simple to install compared to metal conduits. Its rigid structure ensures long-lasting protection for electrical systems, making it a cost-effective and reliable choice for contractors and electricians. Proper installation adheres to safety standards, ensuring optimal performance and compliance with electrical codes.

Importance of Proper Installation

Proper installation of PVC electrical conduit is crucial for ensuring the safety and efficiency of electrical systems. It prevents fire hazards, electrical failures, and ensures compliance with safety standards. Correct installation techniques, as outlined in the PVC Electrical Conduit Installation Guide PDF, guarantee the integrity and longevity of the system. Improper installation can lead to system malfunctions, safety risks, and costly repairs. Adhering to guidelines ensures secure connections, protection from environmental factors, and optimal performance of the electrical infrastructure.

Understanding PVC Conduit Basics

PVC conduit is a durable, non-conductive piping system used for protecting electrical wires. It is resistant to corrosion, chemicals, and environmental factors, making it ideal for various installations. The PVC Electrical Conduit Installation Guide PDF provides foundational knowledge on its specifications, applications, and safety standards, ensuring a solid understanding of its role in electrical systems.

Types of PVC Conduit

PVC conduit is available in various types, each designed for specific applications. Rigid PVC conduit is the most common, offering exceptional strength and durability for underground and commercial installations. Flexible PVC conduit is ideal for tight spaces and areas requiring bends. Schedule 40 and Schedule 80 PVC conduits differ in wall thickness, with Schedule 80 being heavier-duty. The PVC Electrical Conduit Installation Guide PDF details these types, ensuring proper selection based on environmental and mechanical requirements for safe and efficient electrical systems.

Key Features and Benefits

PVC conduit offers exceptional durability, resistance to corrosion, and lightweight construction, making it ideal for electrical installations. Its chemical resistance ensures longevity in harsh environments, while fire-resistant properties enhance safety. PVC conduits are versatile, suitable for underground and above-ground applications, and are cost-effective compared to metal alternatives. They also require minimal maintenance, reducing long-term costs. The PVC Electrical Conduit Installation Guide PDF highlights these benefits, emphasizing their reliability and adaptability for various electrical systems, ensuring efficient and safe installations across different settings.

Materials and Tools Required

Key materials include PVC conduit pipes, fittings, couplers, and adapters. Essential tools are pipe cutters, hacksaws, and solvent weld sets. The PVC Electrical Conduit Installation Guide PDF details these requirements for a successful setup.

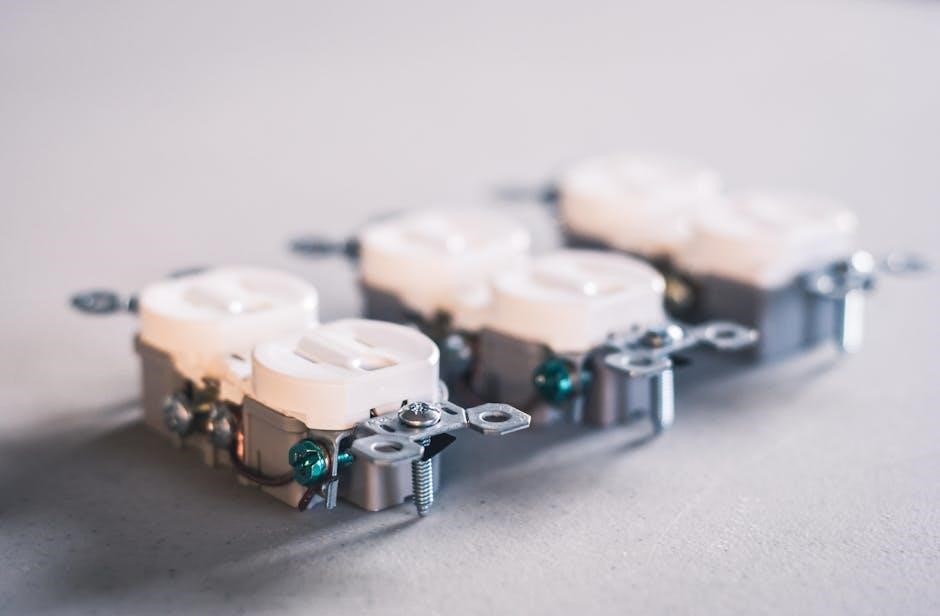

Essential Materials for Installation

The primary materials needed for PVC conduit installation include rigid PVC conduit pipes, fittings such as elbows and tees, couplers, and adapters. Other necessities are conduit seals, end caps, and bushings to protect wires. The PVC Electrical Conduit Installation Guide PDF specifies the correct types of PVC compounds and sizes for various applications. Additionally, lubricants and solvents for solvent welding are required to ensure proper connections. These materials must meet local electrical codes and standards to guarantee safety and system integrity.

Specialized Tools Needed

Installing PVC conduit requires specific tools to ensure precise and efficient work. Essential tools include a conduit cutter or handsaw for cutting, a conduit bender for shaping, and a solvent weld applicator for bonding. A PVC pipe cutter is ideal for clean cuts, while a utility knife can deburr edges. A conduit bending spring helps avoid kinking during manual bends. Additionally, a tape measure, marker, and wrench are necessary for accurate measurements and secure connections. The PVC Electrical Conduit Installation Guide PDF details these tools, ensuring proper preparation for a successful installation process.

Safety Considerations

Always wear Personal Protective Equipment (PPE) like gloves, safety glasses, and a dust mask when handling PVC conduit. Ensure proper ventilation and avoid inhaling fumes from solvents or cutting processes. Follow all electrical safety standards to prevent shocks or fires. Use appropriate tools and equipment to maintain control during cutting and bending. Regularly inspect tools and materials for damage to ensure a safe working environment. Adhere to local regulations and guidelines outlined in the PVC Electrical Conduit Installation Guide PDF.

General Safety Practices

Adhere to safety guidelines when installing PVC electrical conduit to prevent accidents. Ensure proper ventilation to avoid inhaling fumes from solvents or cutting processes. Keep the work area clean and clear of debris to minimize tripping hazards. Use tools and equipment responsibly, following manufacturer instructions. Regularly inspect tools for damage and maintain a safe working environment. Always follow electrical safety standards to prevent shocks or fires. Refer to the PVC Electrical Conduit Installation Guide PDF for detailed safety protocols and best practices.

Personal Protective Equipment (PPE)

Wearing proper Personal Protective Equipment (PPE) is crucial during PVC conduit installation. Use safety glasses to protect eyes from debris and chemical splashes. Gloves prevent skin irritation and provide grip when handling materials. A dust mask is essential when cutting or sanding PVC to avoid inhaling particles. Steel-toe boots protect feet from heavy tools and materials. Ensure all PPE meets industry standards for safety. Refer to the PVC Electrical Conduit Installation Guide PDF for specific PPE recommendations to maintain a safe working environment.

Installation Process

The PVC conduit installation process involves site preparation, cutting, bending, and securing the conduit. Proper techniques ensure a safe and efficient electrical system setup.

Site Preparation

Site preparation is crucial for a smooth PVC conduit installation. Begin by planning the layout and clearing the area of debris. Mark the conduit routes accurately, ensuring they align with electrical plans. Check for underground obstacles and measure distances precisely. Verify local building codes and safety regulations. Prepare all necessary materials and tools, and ensure the work area is safe and accessible. Proper site preparation prevents delays and ensures compliance with installation guidelines outlined in the PVC Electrical Conduit Installation Guide PDF.

Cutting and Bending PVC Conduit

Cutting and bending PVC conduit requires precision to maintain its integrity. Use a hacksaw, pipe cutter, or power saw for clean cuts, ensuring smooth edges to prevent cracking. For bending, apply heat using a conduit bender or heat gun to make the PVC pliable. Avoid excessive bending to prevent kinking or damage. Follow the PVC Electrical Conduit Installation Guide PDF for specific techniques and temperature guidelines to achieve professional results and ensure safe, durable electrical connections.

Securing the Conduit

Securing PVC conduit properly is essential for maintaining the integrity of electrical systems. Use approved fittings and supports to fasten the conduit at regular intervals, ensuring it remains stable and protected from environmental stress. The PVC Electrical Conduit Installation Guide PDF outlines specific spacing and anchoring requirements to prevent sagging and damage. Properly securing the conduit also helps in maintaining the desired pathways for wires, ensuring compliance with safety standards and prolonging the system’s lifespan.

Connecting and Sealing

Connecting and sealing PVC conduit ensures electrical integrity. The PVC Electrical Conduit Installation Guide PDF provides precise methods for secure connections and watertight seals, enhancing system reliability and safety.

Using Couplers and Adapters

Couplers and adapters are essential for connecting PVC conduit sections and transitioning between different sizes or types. The PVC Electrical Conduit Installation Guide PDF outlines proper techniques for installing these components. Couplers are used to join straight conduit runs, while adapters facilitate connections to fittings or equipment. Ensure all connections are secure and properly sealed to maintain electrical continuity and prevent moisture ingress. Solvent welding is often recommended for a watertight seal. The guide provides detailed steps to ensure correct installation and system integrity.

Solvent Welding Techniques

Solvent welding is a critical process for creating strong, permanent bonds in PVC conduit connections. The PVC Electrical Conduit Installation Guide PDF emphasizes proper techniques to ensure leak-proof joints. Apply solvent cement evenly to both surfaces, align the pieces quickly, and hold them firmly to prevent misalignment. The guide stresses the importance of using compatible solvents and following safety precautions to avoid fumes. Proper curing time is essential for achieving maximum bond strength, ensuring the system’s reliability and durability over time.

Inspection and Testing

Post-installation checks ensure PVC conduit systems meet safety and performance standards. The guide recommends visual inspections, pressure tests, and electrical continuity checks to verify integrity and reliability.

Post-Installation Checks

After installing PVC electrical conduit, conduct thorough inspections to ensure system integrity. Verify that all conduits are securely fastened and properly aligned. Check for visible damage, cracks, or misalignments that could compromise performance. Inspect couplers, connectors, and seals for tightness and integrity. Ensure all wires are correctly routed and protected within the conduit. Review the PVC Electrical Conduit Installation Guide PDF for specific post-installation procedures, including pressure tests if applicable. Proper checks ensure long-term reliability and compliance with safety standards.

Testing for Integrity

Testing the integrity of PVC electrical conduit ensures a safe and reliable system. Conduct pressure tests to verify the conduit’s ability to withstand required loads. Inspect all connections and joints for leaks or weaknesses. Use continuity tests to confirm proper electrical pathways. Refer to the PVC Electrical Conduit Installation Guide PDF for specific testing protocols. These steps help identify potential issues before they lead to system failures. Proper testing ensures compliance with electrical codes and guarantees long-term performance and safety of the installed conduit system.

Common Mistakes to Avoid

Improper cutting, inadequate bending, and incorrect solvent welding are common errors. These mistakes can compromise the conduit’s integrity and lead to system failures. Always refer to the PVC Electrical Conduit Installation Guide PDF for solutions and best practices to ensure a safe and reliable installation.

Installation Errors and Solutions

Common installation errors include improper cutting, insufficient heating during bending, and incorrect solvent welding techniques. These issues can lead to weak joints, leaks, or conduit damage. To resolve these, ensure proper tool usage, follow temperature guidelines for bending, and apply solvent welding materials correctly. Additionally, inadequate support or misalignment during installation can cause system failure. Always refer to the PVC Electrical Conduit Installation Guide PDF for detailed solutions and best practices to prevent such mistakes and ensure a durable, reliable electrical system.

Referencing the PVC Electrical Conduit Installation Guide PDF

The PVC Electrical Conduit Installation Guide PDF is a vital resource, offering detailed instructions and best practices for safe and compliant installations. It covers cutting, bending, and solvent welding, ensuring professionals achieve durable electrical systems. The guide provides troubleshooting tips and compliance guidelines, making it an essential tool for contractors and engineers. By following its recommendations, installers can avoid common errors and maintain high standards of quality and safety in their work.

Key Sections of the Guide

The PVC Electrical Conduit Installation Guide PDF includes essential sections on cutting, bending, and solvent welding techniques. It covers site preparation, securing methods, and the use of couplers and adapters. The guide also details post-installation checks and testing procedures to ensure system integrity. Additional sections address common mistakes and provide troubleshooting solutions. Compliance with safety standards and best practices is emphasized throughout. This comprehensive resource offers practical guidance for professionals, ensuring efficient and safe PVC conduit installations. Its clear instructions and detailed diagrams make it an indispensable tool for electricians and contractors.

Using the Guide for Compliance

The PVC Electrical Conduit Installation Guide PDF is designed to ensure compliance with industry standards and regulations. It outlines requirements for materials, installation practices, and safety protocols. By following the guide, professionals can adhere to local and national electrical codes, minimizing risks and ensuring system reliability. The document also provides updates on the latest standards, helping users stay informed and compliant. This makes it an essential resource for maintaining legal and safety compliance in PVC conduit installations.

The PVC Electrical Conduit Installation Guide PDF serves as a vital resource for ensuring safe, efficient, and compliant installations. It provides comprehensive insights into best practices, materials, and techniques, making it indispensable for professionals. By adhering to the guide, electricians and contractors can achieve durable and reliable electrical systems. This document not only simplifies complex processes but also ensures adherence to industry standards, making it a cornerstone for successful PVC conduit installations.