Ingersoll Rand air compressors are renowned for durability and performance, supported by comprehensive manuals that guide users through operation, maintenance, and troubleshooting, ensuring optimal functionality and safety.

1.1 Overview of Ingersoll Rand as a Brand

Ingersoll Rand is a trusted brand with over 160 years of history, built through innovation and strategic acquisitions. Known for reliability and durability, the company offers market-leading solutions across industries globally. With a strong focus on customer satisfaction, Ingersoll Rand provides high-quality air compressors and related products, ensuring optimal performance and efficiency for industrial and commercial applications.

1.2 Importance of the Ingersoll Rand Air Compressor Manual

The Ingersoll Rand Air Compressor Manual is essential for safe and efficient operation. It provides detailed instructions for installation, maintenance, and troubleshooting, ensuring optimal performance. The manual also outlines safety precautions to prevent accidents and prolong equipment life. By following the guidelines, users can comply with manufacturer recommendations, maximizing productivity and warranty compliance while minimizing operational risks.

Key Features of the Ingersoll Rand Air Compressor

Ingersoll Rand air compressors are known for durability, high performance, and reliability. They feature advanced designs, energy efficiency, and robust construction, ensuring consistent operation in demanding environments.

2.1 Types of Air Compressors Available

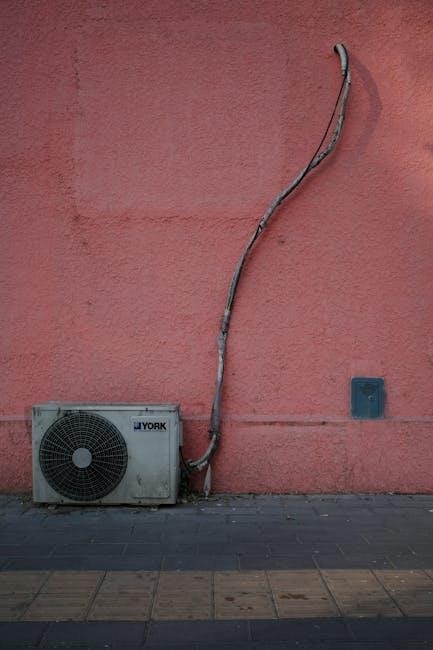

Ingersoll Rand offers a diverse range of air compressors, including rotary screw, reciprocating, and portable models. These compressors cater to various industrial needs, ensuring reliable performance. They are designed for energy efficiency and durability, making them suitable for heavy-duty applications. Each type is tailored to specific industries, providing consistent air pressure and flow, while maintaining minimal operational noise and long-lasting reliability.

- Rotary screw compressors for continuous operation.

- Reciprocating compressors for smaller-scale applications.

- Portable options for flexibility and convenience.

2.2 Technical Specifications and Capabilities

Ingersoll Rand air compressors boast impressive technical specifications, including high-flow rates and pressure capacities. Models like the UP6 offer 20 HP and 122 CFM at 150 psi, while others provide variable speed drives for energy efficiency. They feature advanced cooling systems and noise-reducing designs, ensuring optimal performance in industrial settings. These compressors are built for durability, with robust construction and compliance with global emission standards.

- High air flow rates for demanding applications.

- Variable speed control for energy savings.

- Low noise operation for industrial environments.

- Compliance with international emission standards.

Installation and Setup Guidelines

Ensure the site is prepared with proper drainage and ventilation. Mount the compressor on a stable, vibration-resistant surface using a flexible system. Follow local building codes and safety standards for installation. Consult the manual for specific electrical and piping requirements to ensure safe and efficient operation.

3.1 Pre-Installation Requirements

Before installing, ensure the site meets safety and technical standards. Verify proper drainage, ventilation, and structural integrity. Check electrical and pneumatic connections for compatibility. Ensure the area is clear of hazards and flammable materials. Review local building codes and environmental regulations. Prepare mounting surfaces and flexible isolation systems to prevent vibration damage. Consult the manual for specific site preparation and foundation requirements to ensure safe operation.

3.2 Step-by-Step Installation Process

Begin by isolating the compressor package from the carrier base using a flexible mounting system to prevent detachment and vibration. Connect electrical and pneumatic systems according to the manual’s specifications. Ensure all components are securely fastened and aligned. Perform a final inspection to verify proper connections and system integrity. Power up the compressor and test its operation under no-load conditions before full deployment.

Operating Instructions

Follow the manual’s guidelines for starting and stopping the compressor, understanding control panels, and adhering to safety protocols. Monitor performance and adjust settings as needed for optimal operation.

4.1 Starting and Stopping the Compressor

Starting the compressor involves powering up, checking settings, and initiating operation. Ensure all safety protocols are followed. Stopping requires gradual shutdown, cooling down, and disconnecting power. Always refer to the manual for specific procedures to avoid damage and ensure safety.

4.2 Understanding Control Panels and Settings

Familiarize yourself with the control panel to monitor and adjust compressor operations. Key components include pressure gauges, start/stop buttons, and LED displays. Settings may vary, but most models allow adjusting pressure levels, startup timers, and automatic shutdowns. The manual provides detailed guidance on configuring these settings for optimal performance and efficiency. Always refer to the manual for specific instructions tailored to your model.

Maintenance and Service

5.1 Routine Maintenance Tasks

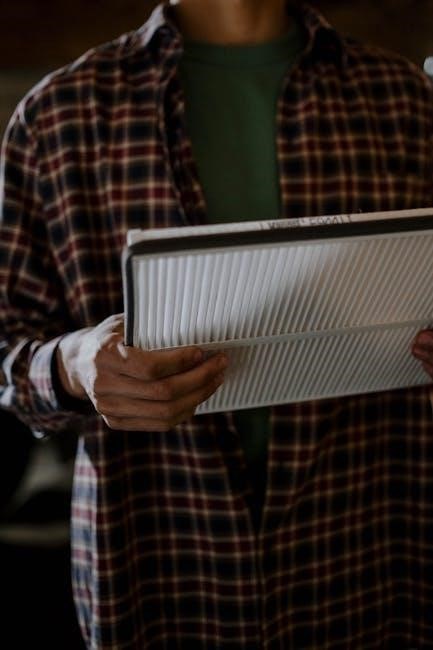

Regular maintenance ensures the air compressor operates efficiently. Daily tasks include checking oil levels and filter conditions. Weekly, inspect belts and hoses for wear. Monthly, replace air filters and drain moisture from tanks. Additionally, monitor vibration levels and ensure proper grounding. Refer to the manual for detailed schedules and procedures to maintain peak performance and prevent unexpected downtime.

5.2 Parts Replacement and Service Intervals

Adhere to the recommended service intervals for optimal performance. Replace air filters every 2,000 hours and oil filters every 1,000 to 2,000 hours. Inspect and replace belts and hoses every 500 hours. Follow the manual’s guidelines for replacing worn or damaged parts. Timely service ensures reliability, extends equipment lifespan, and prevents costly repairs. Always use genuine Ingersoll Rand parts for compliance and performance.

Troubleshooting Common Issues

Consult the manual for diagnosing common problems like low pressure or overheating. Check error codes and perform routine maintenance to resolve issues promptly and ensure smooth operation.

6.1 Identifying and Resolving Operational Problems

Refer to the manual for troubleshooting common issues like low air pressure or overheating. Check intake filters, ensure proper cooling, and monitor for abnormal noises. Address error codes promptly and perform routine maintenance tasks, such as oil level checks and belt inspections. For persistent problems, consult the detailed diagnostic guides or contact Ingersoll Rand support for assistance. Always use genuine parts for repairs to maintain performance and safety.

6.2 Error Codes and Solutions

The manual provides a detailed list of error codes, such as temperature warnings or low air pressure alerts. Each code is accompanied by step-by-step solutions, ensuring quick resolution. For example, error code “E01” indicates high discharge temperature, requiring immediate cooling system inspection. Always refer to the manual or contact Ingersoll Rand support for accurate diagnostics and repair guidance to avoid further complications. Regular maintenance can prevent many issues.

Safety Guidelines

Adhering to safety guidelines ensures safe operation. Avoid hazardous environments and follow manual instructions for handling electrical components and air pressure systems to prevent accidents.

7.1 General Safety Precautions

Always follow safety guidelines to ensure safe operation. Keep the compressor away from hazardous environments and avoid using communication devices emitting over 7.5 volts per meter near it. Ensure proper installation, ventilation, and grounding to prevent accidents. Regularly inspect components and adhere to manual instructions to avoid contamination and injury. Safety measures are critical for optimal performance and user protection.

7.2 Hazardous Environment Considerations

Ensure the compressor is isolated from the carrier base using a flexible mounting system to prevent detachment. Avoid operating in high-vibration or extreme-temperature environments. Check for contaminants in intake air, as they can pose risks. For explosive environments, ATEX-compliant models like the 2130 series are recommended. Always follow installation guidelines and consult the manual for specific hazardous environment requirements to ensure safe operation and compliance with safety standards.

Warranty and Support Information

Ingersoll Rand air compressors are backed by comprehensive warranties and dedicated customer support. Contact their authorized representatives for detailed warranty terms, service inquiries, or technical assistance.

8.1 Warranty Coverage and Terms

Ingersoll Rand air compressors come with comprehensive warranty coverage, ensuring protection for parts and labor. The warranty typically covers defects in materials and workmanship, with specific terms varying by model. Proper installation and maintenance, as outlined in the manual, are essential to uphold warranty validity. Contact Ingersoll Rand customer support for detailed warranty terms and conditions.

8.2 Contacting Ingersoll Rand Customer Support

For assistance, visit the official Ingersoll Rand website or contact their customer support team directly. The Moscow office is located at 101000, Russia, Moscow, Miasnitskaya St., 32/1, and can be reached at (095) for inquiries. Additional resources, including manuals and troubleshooting guides, are available online to ensure optimal support for your air compressor needs.

Environmental and Compliance Considerations

Ingersoll Rand air compressors adhere to strict emission standards, ensuring energy efficiency and environmental compliance. Proper disposal and recycling guidelines are provided to minimize ecological impact, promoting sustainable practices.

9.1 Emission Standards and Compliance

Ingersoll Rand air compressors are designed to meet strict emission standards, ensuring energy efficiency and reduced environmental impact. The manual provides guidelines for operation and maintenance to comply with regulatory requirements, minimizing ecological footprint while maintaining performance and reliability.

9.2 Proper Disposal and Recycling Guidelines

Proper disposal and recycling of Ingersoll Rand air compressors are crucial for environmental sustainability. Users should consult local regulations for hazardous waste disposal, ensuring harmful materials are safely handled. Recycling programs or authorized centers can process metal and electronic components. Avoid landfill disposal to minimize ecological impact. Always refer to the manual or contact customer support for detailed recycling instructions and guidelines.

Accessories and Optional Features

Ingersoll Rand air compressors offer various accessories, including filters, hoses, and control panels, to enhance performance. Optional features like upgraded cooling systems and remote monitoring improve efficiency and customization.

10;1 Recommended Accessories for Optimal Performance

To maximize the efficiency of your Ingersoll Rand air compressor, consider essential accessories like high-efficiency air filters, premium-grade hoses, and advanced control panels. These components ensure improved air quality, reduced pressure drop, and enhanced system control. Additionally, optional features such as upgraded cooling systems and remote monitoring devices can further customize your compressor to meet specific operational demands and environmental conditions.

10.2 Upgrading Your Air Compressor System

Upgrading your Ingersoll Rand air compressor system can enhance performance and adapt to evolving needs. Consider adding advanced controllers like the Xe-70M for improved connectivity and asset management. Rotary screw compressors can be upgraded with energy-efficient motors or advanced cooling systems. Optional features such as remote monitoring devices and smart sensors provide real-time data, enabling better control and predictive maintenance, ensuring optimal productivity and longevity.

Training and Resources

Ingersoll Rand offers comprehensive operator manuals, PDF guides, and customer support to enhance user skills and productivity. Additional resources include troubleshooting tips and maintenance documentation for optimal performance.

11.1 Operator Training Recommendations

Proper training is essential for safe and efficient operation of Ingersoll Rand air compressors. Operators should thoroughly read the manual, participate in hands-on training, and attend regular refresher sessions. Utilize online resources, such as PDF guides and video tutorials, to enhance understanding. Encourage operators to complete certified training programs and seek guidance from experienced professionals to ensure compliance with safety standards and optimal equipment performance.

11.2 Additional Resources and Documentation

Ingersoll Rand offers extensive resources, including PDF manuals, CAD drawings, and brochures, to support optimal use of their air compressors. Users can access product specifications, warranty guides, and maintenance schedules online. Additional materials, such as emissions compliance documents and troubleshooting guides, are available for download. For further assistance, customers can contact Ingersoll Rand’s customer support or visit authorized resellers for personalized guidance and accessories.

Frequently Asked Questions

Frequently Asked Questions provide quick answers to common inquiries about Ingersoll Rand air compressor manuals, troubleshooting, and operational guidelines, ensuring easy access to essential information.

12.1 Common Queries About the Manual

This section addresses common questions about the Ingersoll Rand air compressor manual, such as where to find it, how to download it, and its importance for proper operation. It also explains the manual’s role in troubleshooting and maintenance, ensuring users understand safety guidelines, technical specifications, and warranty details. Reading the manual is crucial for safe and efficient compressor operation.

12.2 Answers to Technical and Operational Questions

This section provides detailed answers to technical and operational questions, such as troubleshooting steps for common issues, understanding error codes, and interpreting technical specifications. It also offers guidance on maintenance schedules, optimal performance tips, and solutions for operational challenges, ensuring users can resolve problems efficiently and maintain their compressor’s peak performance.

13.1 Final Tips for Maximizing Compressor Efficiency

To maximize compressor efficiency, ensure regular maintenance tasks are performed, such as filter cleaning and oil checks. Always follow the manual’s guidelines for optimal performance. Proper installation and operation within specified limits are crucial. Regularly inspect for air leaks and address them promptly. Store the compressor in a clean, dry environment to prevent damage. Adhere to the recommended service intervals for parts replacement to maintain peak functionality and safety.