Briggs & Stratton single cylinder OHV engines power countless outdoor tools; a dedicated PDF repair manual unlocks efficient troubleshooting and maintenance procedures.

Accessing a detailed manual, like the Briggs & Stratton Vanguard twin cylinder OHV service repair manual, is crucial for maximizing engine lifespan and performance.

This guide will illuminate the benefits of utilizing a proper manual, streamlining repairs, and ensuring optimal functionality of your small engine equipment.

What is a Briggs & Stratton Single Cylinder OHV Engine?

Briggs & Stratton single cylinder OHV (Overhead Valve) engines represent a cornerstone of small engine technology, widely utilized in lawnmowers, generators, pressure washers, and various other outdoor power equipment.

These engines are characterized by their compact design, relative simplicity, and robust performance, making them a popular choice for both residential and commercial applications.

The OHV configuration positions the valves in the cylinder head, directly above the piston, enhancing combustion efficiency and contributing to increased power output compared to older engine designs.

Understanding the fundamental principles of these engines is paramount for effective repair and maintenance, and a comprehensive PDF repair manual serves as an invaluable resource for diagnosing issues and performing necessary adjustments.

A manual, such as the Briggs & Stratton Vanguard twin cylinder OHV service repair manual, details the intricacies of these engines.

Why a Repair Manual is Essential

A dedicated Briggs & Stratton single cylinder OHV repair manual, often available as a PDF, is absolutely essential for anyone undertaking maintenance or repairs on these engines.

These manuals provide detailed, step-by-step instructions, accompanied by diagrams and illustrations, enabling even novice users to confidently tackle common issues.

Attempting repairs without a proper manual can lead to further damage, incorrect assembly, and potentially unsafe operating conditions.

Access to accurate torque specifications, troubleshooting flowcharts, and parts lists, found within a manual like the Briggs & Stratton Vanguard twin cylinder OHV service repair manual, ensures repairs are performed correctly.

Ultimately, a repair manual saves time, money, and frustration, extending the lifespan of your engine and ensuring reliable performance.

Scope of this Guide

This guide focuses specifically on the repair and maintenance of Briggs & Stratton single cylinder OHV (Overhead Valve) engines, utilizing the information found within a comprehensive PDF repair manual.

We will cover locating the correct manual for your specific engine model, identifying essential tools, and diagnosing common problems like starting issues, power loss, and overheating.

Step-by-step repair procedures will be detailed, including carburetor cleaning, spark plug replacement, and air filter maintenance.

Furthermore, we will explore more advanced topics such as piston replacement, valve adjustment, and governor repair, referencing the Briggs & Stratton Vanguard twin cylinder OHV service repair manual for detailed instructions.

This guide aims to empower users with the knowledge and resources to effectively maintain and repair their engines.

Locating the Correct Repair Manual (PDF)

Finding the right PDF manual is vital; explore the official Briggs & Stratton website and trusted third-party retailers for accurate engine-specific documentation.

Official Briggs & Stratton Website

Briggs & Stratton’s official website serves as the primary and most reliable source for authentic repair manuals in PDF format. Navigating their support section allows users to directly search for documentation based on the specific model number of their single cylinder OHV engine.

The website often provides downloadable manuals free of charge, ensuring access to the latest revisions and updates. Utilizing the model number is paramount for accurate results, as Briggs & Stratton produces a vast range of engines with varying specifications.

Furthermore, the official site may offer interactive troubleshooting guides and parts diagrams, supplementing the comprehensive information found within the PDF repair manual. This direct access guarantees compatibility and minimizes the risk of utilizing incorrect or outdated repair procedures.

Third-Party Retailers & Online Databases

While the official Briggs & Stratton website is preferred, numerous third-party retailers and online databases offer PDF versions of single cylinder OHV repair manuals. Platforms like eBay, Amazon, and specialized small engine parts retailers frequently list both physical copies and downloadable PDF files.

Online databases dedicated to service manuals often compile a wide selection, though verifying the manual’s accuracy and compatibility with your specific engine model is crucial. Caution should be exercised when downloading from unofficial sources to avoid potentially corrupted files or malware.

Comparing prices and checking user reviews can help identify reputable sellers and ensure the manual’s quality. Remember to always confirm the model number matches before purchasing or downloading any PDF repair manual.

Identifying Your Engine Model Number

Locating your Briggs & Stratton single cylinder OHV engine’s model number is paramount when searching for the correct PDF repair manual. This unique identifier ensures you obtain a manual specifically tailored to your engine’s configuration.

The model number is typically stamped or affixed to the engine’s valve cover, blower housing, or directly onto the engine block. It’s usually a combination of letters and numbers, such as “190402”. Carefully inspect these areas, and consult your equipment’s owner’s manual for precise location guidance.

Accurate identification prevents compatibility issues and ensures the repair procedures and diagrams within the PDF manual align with your engine’s specifications. Without the correct model number, you risk using incorrect information, potentially causing further damage.

Understanding Manual Versions & Updates

Briggs & Stratton frequently releases updated versions of their single cylinder OHV engine PDF repair manuals to reflect design changes, improved procedures, and new information. Utilizing the most current version is crucial for accurate repairs.

Older manuals may contain outdated instructions or diagrams that don’t align with your engine’s specific build date. Check the manual’s publication date and compare it to your engine’s manufacturing date, often found alongside the model number.

The official Briggs & Stratton website is the best source for the latest PDF manuals. Regularly check for updates, even if you already possess a manual, to ensure you have the most reliable information available for successful engine maintenance and repair.

Essential Tools for Repair

Repairing a Briggs & Stratton engine requires basic hand tools, specialized equipment like a flywheel puller, and crucial safety gear for effective maintenance;

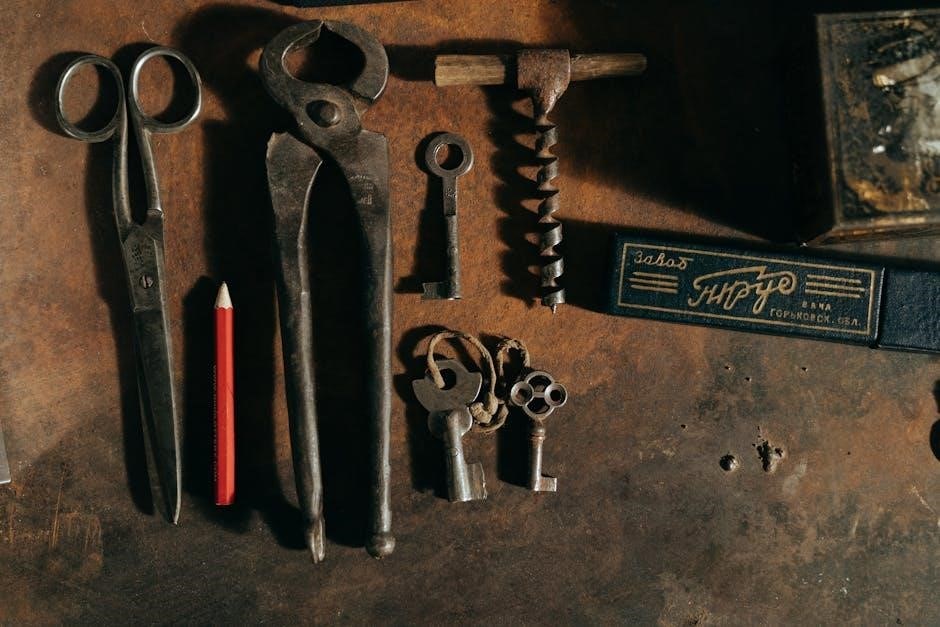

Basic Hand Tools (Wrenches, Screwdrivers, Pliers)

A foundational toolkit is paramount when tackling Briggs & Stratton engine repairs, and a quality set of hand tools forms the core of this arsenal. Combination wrenches, in both standard and metric sizes, are essential for loosening and tightening various engine components, including bolts on the carburetor and governor.

Screwdrivers – both flathead and Phillips head – are indispensable for accessing and adjusting internal parts, such as the carburetor settings and spark plug. Pliers, encompassing needle-nose and slip-joint varieties, provide versatility for gripping, bending, and manipulating wires and small components.

Having a range of sizes within each tool type ensures compatibility with the diverse fasteners found on these engines. Socket sets, with various extensions, can also significantly simplify access to recessed bolts. Remember, using the correct size tool prevents damage to fasteners and ensures a secure repair.

Specialized Tools (Flywheel Puller, Compression Tester)

Beyond basic hand tools, certain specialized instruments are crucial for comprehensive Briggs & Stratton engine repair, as detailed in a proper PDF manual. A flywheel puller is absolutely necessary for removing the flywheel, enabling access to the ignition module and other critical components. Attempting removal without this tool risks severe engine damage.

A compression tester is invaluable for diagnosing engine health; low compression indicates potential issues with piston rings, valves, or cylinder walls. This test, guided by the repair manual’s specifications, pinpoints internal problems.

Other helpful specialized tools include a valve spring compressor, a timing light (for models with electronic ignition), and a feeler gauge for precise valve adjustments. Investing in these tools, alongside a detailed manual, empowers you to perform more complex repairs effectively and safely.

Safety Equipment (Gloves, Goggles)

Prioritizing safety is paramount when undertaking any Briggs & Stratton engine repair, and a PDF repair manual will often highlight necessary precautions. Always wear appropriate gloves to protect your hands from sharp edges, hot surfaces, and harsh chemicals like gasoline and oil; Nitrile gloves offer excellent resistance to these substances.

Goggles or a face shield are essential to shield your eyes from flying debris during disassembly or cleaning. Small particles can cause serious eye injury. Proper ventilation is also crucial when working with fuels and solvents; work in a well-ventilated area.

Furthermore, consider wearing hearing protection, especially when operating the engine for testing purposes. A sturdy workbench and proper lighting contribute to a safer working environment. Refer to the manual for specific safety warnings related to each repair procedure.

Common Briggs & Stratton OHV Engine Problems

Briggs & Stratton OHV engines frequently experience starting issues, power loss, excessive smoke, or overheating; a PDF manual aids diagnosis and repair.

Starting Issues

Starting problems with Briggs & Stratton single cylinder OHV engines are remarkably common, often stemming from a handful of easily addressable causes. A comprehensive PDF repair manual is invaluable for systematically diagnosing these issues. Frequently, the culprit is a dirty or clogged carburetor, preventing the proper fuel-air mixture from reaching the cylinder.

Another frequent offender is a fouled spark plug, unable to generate the necessary spark for ignition. The manual provides detailed instructions for spark plug inspection, cleaning, and replacement. Low compression, potentially due to worn piston rings or valve issues, can also hinder starting. Utilizing a compression tester, as detailed in the manual, will quickly reveal compression deficiencies.

Furthermore, a blocked fuel line or a malfunctioning fuel pump can starve the engine of fuel. The repair manual offers guidance on fuel system troubleshooting. Finally, ensure the choke is functioning correctly, especially in colder weather. A PDF manual provides exploded diagrams and step-by-step procedures for all these repairs.

Loss of Power

Experiencing a loss of power in your Briggs & Stratton single cylinder OHV engine indicates a performance issue requiring investigation. A detailed PDF repair manual is essential for pinpointing the root cause. Often, diminished power stems from a partially clogged air filter, restricting airflow to the carburetor. The manual illustrates proper air filter maintenance and replacement procedures.

A dirty carburetor, similar to starting issues, can also contribute to power loss by disrupting the fuel-air mixture. The manual provides thorough carburetor cleaning and adjustment instructions. Worn or damaged spark plugs can also reduce engine efficiency. Compression loss, due to worn rings or valves, significantly impacts power output; the manual details compression testing;

Furthermore, a restricted exhaust system or a malfunctioning governor can limit engine performance. The repair manual offers diagnostic steps and repair procedures for these components. Utilizing the manual’s troubleshooting flowcharts will expedite the repair process.

Excessive Smoke

Excessive smoke emanating from your Briggs & Stratton single cylinder OHV engine signals an underlying problem demanding attention. A comprehensive PDF repair manual is invaluable for accurate diagnosis. Blue smoke typically indicates oil entering the combustion chamber, often due to worn piston rings or valve stem seals. The manual details piston and ring replacement procedures, alongside oil seal replacement guidance.

Black smoke suggests a rich fuel mixture, potentially caused by a malfunctioning carburetor or a clogged air filter. The manual provides detailed carburetor adjustment instructions and air filter maintenance procedures. White smoke can signify coolant entering the combustion chamber, indicating a head gasket failure or a cracked cylinder block.

The repair manual’s diagrams and illustrations aid in identifying these components. Following the manual’s troubleshooting flowcharts will help isolate the source of the smoke and guide you through the necessary repairs efficiently.

Overheating

Overheating in a Briggs & Stratton single cylinder OHV engine can lead to severe damage; a detailed PDF repair manual is essential for swift diagnosis and repair. Common causes include insufficient cooling, a clogged cooling fin area, or a malfunctioning governor. The manual provides detailed illustrations of the engine’s cooling system and governor components.

Low oil levels can also contribute to overheating, so always verify oil levels before operation. The manual emphasizes the importance of maintaining proper lubrication. A faulty carburetor can cause the engine to run lean, increasing combustion temperatures. Refer to the carburetor cleaning and adjustment section within the repair manual.

Utilize the manual’s troubleshooting flowcharts to systematically identify the root cause. Torque specifications are crucial when reassembling components to ensure proper heat dissipation and prevent future overheating issues.

Repair Procedures ⎯ Step-by-Step

Utilizing a Briggs & Stratton PDF manual, follow precise instructions for carburetor cleaning, spark plug replacement, air filter maintenance, and valve adjustments.

Carburetor Cleaning & Adjustment

The carburetor is often the source of starting and running issues in Briggs & Stratton engines; a PDF repair manual provides detailed disassembly instructions.

Begin by carefully disconnecting the fuel line, noting its orientation, and then removing the carburetor from the engine, referencing the manual’s diagrams.

Thoroughly clean all carburetor components – jets, passages, and the float bowl – using carburetor cleaner, ensuring no residue remains that could impede fuel flow.

Pay close attention to the main jet and idle jet, verifying they are clear; compressed air can assist in clearing stubborn blockages, as shown in the manual.

Reassemble the carburetor, carefully following the manual’s torque specifications for all screws and bolts, preventing leaks or damage.

Adjust the idle speed and mixture screws according to the manual’s guidelines, achieving smooth engine operation and optimal fuel efficiency.

Always consult the PDF manual for your specific engine model, as adjustments vary.

Spark Plug Replacement

A faulty spark plug is a common cause of engine misfires; your Briggs & Stratton PDF repair manual details the correct replacement procedure.

First, disconnect the spark plug wire, ensuring a firm grip on the boot to avoid damage; the manual illustrates proper disconnection techniques.

Use a spark plug socket to carefully remove the old spark plug, noting its condition for clues about engine health – fouling indicates potential issues.

Check the gap of the new spark plug using a feeler gauge, adjusting it to the specification listed in your engine’s PDF manual for optimal ignition.

Apply a small amount of anti-seize compound to the spark plug threads, preventing future seizing and facilitating removal.

Carefully thread the new spark plug into the cylinder head by hand, then tighten it to the torque specified in the manual using a torque wrench.

Reconnect the spark plug wire securely, ensuring a tight connection for reliable ignition.

Air Filter Maintenance

Maintaining a clean air filter is vital for engine performance; your Briggs & Stratton PDF repair manual provides detailed instructions for this task.

Locate the air filter housing, typically on top of or beside the engine, and remove the cover, referencing the manual’s diagrams for clarity.

Inspect the air filter element – if it’s paper, replace it if dirty or damaged; foam filters can often be washed with soap and water, then oiled.

For paper filters, ensure the new filter is seated correctly within the housing, creating a proper seal to prevent unfiltered air from entering.

If using a foam filter, apply a light coat of air filter oil, ensuring even distribution for optimal dust and debris capture.

Reinstall the air filter cover, securing it tightly to prevent air leaks; the manual specifies correct fastening procedures.

Regular air filter maintenance, as outlined in your PDF manual, ensures efficient combustion and prolongs engine life.

Valve Adjustment

Proper valve adjustment, detailed within your Briggs & Stratton PDF repair manual, is crucial for optimal engine compression and performance.

Consult the manual for specific valve clearance specifications for your engine model; these vary significantly.

Remove the valve cover, carefully noting the position of any gaskets or seals for correct reinstallation, as shown in the manual’s illustrations.

Rotate the engine to Top Dead Center (TDC) on the compression stroke, using the flywheel and referencing the manual’s guidance.

Use a feeler gauge to measure the valve clearance between the valve stem and the rocker arm; adjust as needed.

Loosen the valve adjustment nut and adjust the clearance until the correct feeler gauge slides in with slight drag.

Retighten the nut, recheck the clearance, and repeat until accurate; reinstall the valve cover with a new gasket if necessary.

Advanced Repair Topics

Delving deeper, the PDF manual guides complex repairs like piston replacement, crankshaft inspection, governor fixes, and meticulous oil seal/gasket procedures.

Piston & Ring Replacement

The repair manual’s detailed diagrams are invaluable when undertaking piston and ring replacement, a task demanding precision. Firstly, the manual stresses the importance of proper cylinder bore measurement to ensure correct piston sizing, preventing premature wear or seizure.

It meticulously outlines the removal of the connecting rod cap, piston, and rings, emphasizing the use of a piston ring compressor for re-installation. Torque specifications for the connecting rod bolts are clearly stated, crucial for maintaining engine integrity.

Furthermore, the PDF guide illustrates proper ring gap orientation and staggering techniques, maximizing compression and minimizing oil consumption. Detailed instructions cover piston pin installation and securing methods, alongside cylinder honing procedures to achieve the optimal surface finish for ring seating. Always refer to the manual for specific model variations and updated procedures.

Connecting Rod & Crankshaft Inspection

The Briggs & Stratton repair manual emphasizes a thorough inspection of the connecting rod and crankshaft during engine disassembly. Specifically, it details how to check for bends or twists in the connecting rod, utilizing precise measurement techniques outlined within the PDF.

Crankshaft inspection focuses on bearing journal surfaces; the manual illustrates identifying scoring, pitting, or ovality, indicating potential bearing failure. It provides guidance on using a micrometer to verify crankshaft journal dimensions against factory specifications.

Furthermore, the manual details checking connecting rod bearing clearances using Plastigage, ensuring proper lubrication and preventing engine knock. Detailed diagrams show how to assess the condition of the crankshaft keyway and flywheel key. Always consult the manual for acceptable wear limits and recommended replacement procedures.

Governor Repair

The Briggs & Stratton single cylinder OHV repair manual dedicates a section to governor repair, crucial for maintaining consistent engine speed under varying loads. The PDF provides exploded views illustrating the governor assembly, identifying components like the governor arm, gear, and weights.

Troubleshooting steps within the manual guide users through checking governor linkage for binding or wear, and inspecting the governor gear for damaged teeth. It details how to test governor spring tension and replace worn components.

Crucially, the manual emphasizes proper governor adjustment procedures, ensuring the engine responds correctly to load changes. Detailed instructions explain how to set the governor linkage to achieve the correct engine speed. Always refer to the manual’s torque specifications when reassembling the governor system.

Oil Seal & Gasket Replacement

The Briggs & Stratton single cylinder OHV repair manual’s PDF version provides comprehensive guidance on oil seal and gasket replacement, vital for preventing oil leaks and maintaining engine compression. Detailed diagrams illustrate the location of various seals and gaskets, including those for the crankshaft, valve cover, and oil pan.

The manual stresses the importance of using the correct replacement parts, referencing part numbers for accurate identification. Step-by-step instructions outline the removal of old seals and gaskets, emphasizing the use of appropriate tools to avoid damage to mating surfaces.

Proper installation techniques, including the application of sealant where necessary, are thoroughly explained. Torque specifications for tightening bolts are clearly indicated, ensuring a leak-proof seal. Following these instructions precisely, as detailed in the manual, is essential for a successful repair.

Using the Repair Manual (PDF) Effectively

A Briggs & Stratton PDF manual unlocks detailed diagrams, troubleshooting flowcharts, and torque specs; mastering these elements ensures successful engine repairs.

Understanding Diagrams & Illustrations

Briggs & Stratton repair manuals heavily rely on detailed diagrams and illustrations to convey complex assembly and disassembly procedures; these visuals are not merely decorative, but essential for accurate repair.

Each component is typically labeled with a corresponding part number, facilitating easy identification and ordering of replacement parts. Pay close attention to exploded views, which showcase how parts fit together in a sequential manner.

Illustrations often highlight critical alignment points and fastener locations, preventing errors during reassembly. Understanding the conventions used – such as cross-hatching for textured surfaces or dotted lines for hidden components – is vital.

Furthermore, many manuals utilize color-coding to differentiate between parts or stages of the repair process. Carefully studying these visuals before commencing any work will significantly improve your chances of a successful outcome and minimize potential damage.

Interpreting Torque Specifications

Briggs & Stratton repair manuals provide precise torque specifications for every fastener, crucial for ensuring proper component clamping force and preventing damage. Ignoring these specifications can lead to loose connections, premature wear, or even catastrophic engine failure.

Torque values are typically expressed in foot-pounds (ft-lbs) or Newton-meters (Nm). Always use a calibrated torque wrench to achieve the specified tightness. Understand the difference between dry and lubricated threads; lubricated threads require a reduced torque value.

The manual will often indicate whether a specific fastener requires thread-locking compound. Pay attention to any notes regarding tightening sequences, especially for multi-bolt assemblies like cylinder heads or flywheels.

Adhering to these torque specifications isn’t merely a recommendation; it’s a necessity for maintaining engine reliability and longevity, as outlined within the PDF repair manual;

Following Troubleshooting Flowcharts

Briggs & Stratton PDF repair manuals incorporate detailed troubleshooting flowcharts, offering a systematic approach to diagnosing engine problems. These charts guide you through a series of questions and tests, narrowing down the potential causes of issues like starting failures or power loss.

Begin at the flowchart’s starting point and answer each question accurately. Follow the arrows to the next step based on your response. These charts often direct you to specific tests, such as checking spark, compression, or fuel delivery.

Carefully note any recommended tests or inspections. Don’t skip steps, as each one is designed to eliminate potential causes. Utilizing these flowcharts saves time and prevents unnecessary component replacement.

Successfully navigating these charts, as detailed in the manual, ensures a logical and efficient repair process, maximizing your chances of a swift resolution.

Safety Precautions within the Manual

Briggs & Stratton PDF repair manuals prioritize safety, dedicating sections to crucial precautions before, during, and after repairs. These manuals consistently emphasize disconnecting the spark plug wire to prevent accidental starting, a vital step for personal safety.

Always wear appropriate personal protective equipment (PPE), including safety goggles and gloves, as highlighted in the manual. Fuel handling requires extreme caution; work in a well-ventilated area and avoid open flames.

The manual details safe procedures for handling hot engine components, preventing burns. Proper tool usage is also stressed, ensuring you utilize the correct tools for each task.

Adhering to these safety guidelines, as outlined in the PDF, minimizes the risk of injury and ensures a secure repair environment. Ignoring these precautions can lead to serious harm.